Ball Charge In Ball Mills What Is

.jpg)

Ball Mill an overview ScienceDirect Topics

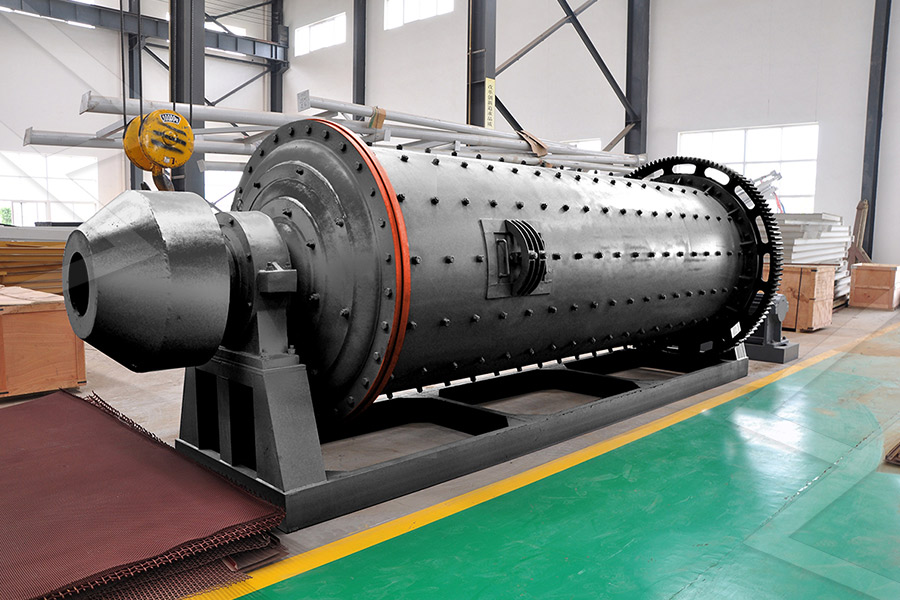

The normal charge of balls is about 5 Mg/m 3 In small mills where very fine grinding is required, pebbles are often used in place of balls In the compound mill, the cylinder is divided into a number of compartments by vertical perforated platesReactive ball milling Reactive ball milling method is to mill starting materials under Ball Milling2001年8月1日 Discrete element method (DEM) modelling has been used to systematically study the effects of changes in mill operating parameters and particle properties on the Charge behaviour and power consumption in ball mills: 2021年3月12日 Ball mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can BALL MILLS Ball mill optimisation Holzinger Consulting

Guidelines for sample amount and ball charge Content

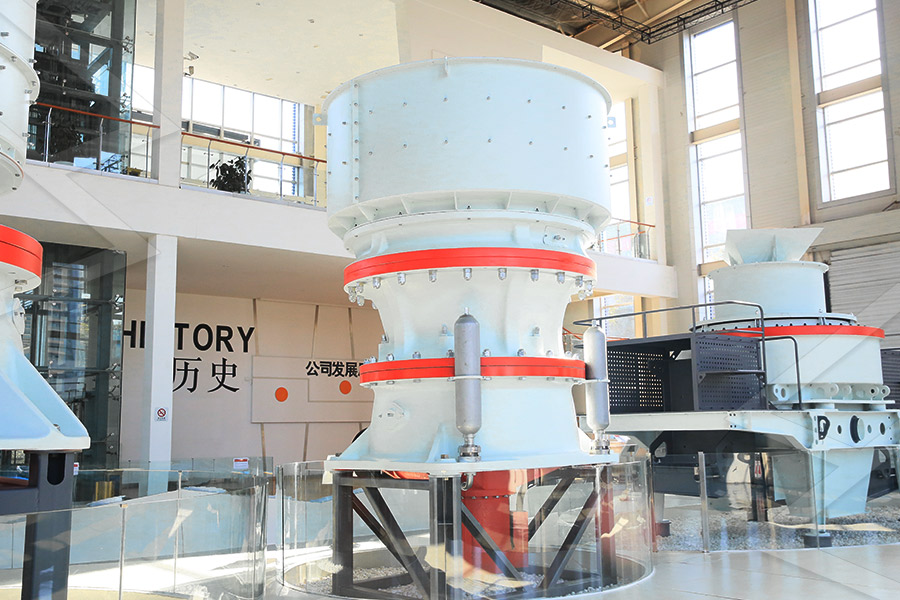

2023年3月24日 grinding results, the MM 500 nano or Planetary Ball Mills should be used (optimized jar geometry) The Mixer Mills are also used for cell disruption of biological 2021年5月8日 Lameck’s work indicated that: Higher torque (power draw) can be achieved with increased packing efficiency – particularly for worn ball media At lower mill speeds, Rethinking Grinding Efficiency in Ball Mills RELO Ball charge optimization : Purpose: Optimization of a ball charge for cement and raw mills with objective of optimizing the grinding efficiency Best Practice: The ball charge in first Ball charge optimization INFINITY FOR CEMENT EQUIPMENTUsually, an SAG mill is charged to 30–35% of its interior volume The grinding balls occupy 5–15% of the volume [10] The charge volume can be estimated by measuring the Mill Charge an overview ScienceDirect Topics

SAG mill ball charge determination and its influence on mill

In semiautogenous grinding (SAG), the grinding mill inventory, (ie volume of total charge, volume of ball charge, etc) is important in determining the optimum operating condition 2020年7月2日 When the mills charge comprising 60% of small balls and 40% of big balls, mill speed has the greatest influence on power consumption When the mill charge is Effects of Ball Size Distribution and Mill Speed and Their Interactions 2022年2月10日 The document discusses ball charge management in ball mill systems It addresses the need to top up the ball charge as balls wear down over time to maintain grinding efficiency and production levels The Ball Charge Management PDF Mill (Grinding)The raw mill will be operate with a much coarser ball charge than the cement mill mainly because of the bigger slot sizes of the partition wall The transition zone consists of 50 mm and 60 mm balls The basis is a 50 mm ball size for 5% residue on the 4 mm sieve In case bigger grains are bypassing the partition through the center grate even Ball charge optimization INFINITY FOR CEMENT EQUIPMENT

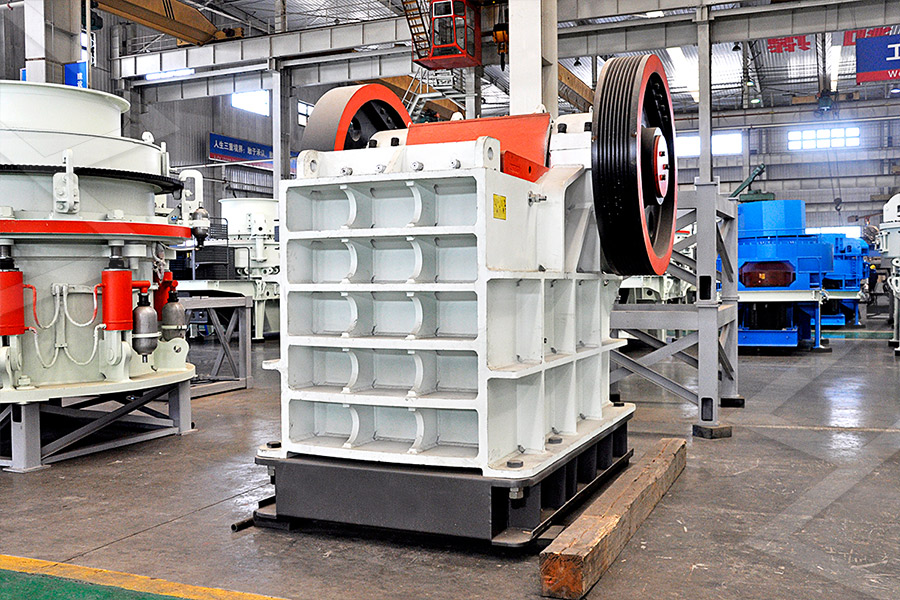

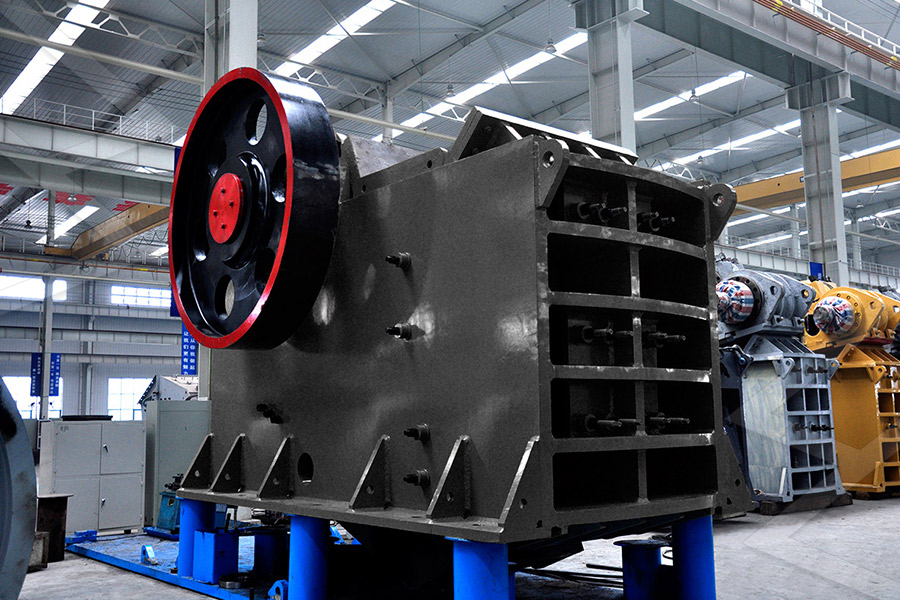

Ball Mills in the Mineral Processing Industry

2024年5月27日 Ball mills are widely used in the beneficiation process for various ores and minerals, including gold, copper, iron, and zinc The TITAN design enables you to run a full process load with a 40% ball 2022年11月30日 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis Ball Mill: Operating principles, components, Autogenous and SemiAutogenous Mills In Mineral Processing Design and Operations (Second Edition), 2016 933 M ill Charge Usually, an SAG mill is charged to 30–35% of its interior volume The grinding balls occupy 5–15% of the volume [10]The charge volume can be estimated by measuring the distance between the top level of the charge and the Mill Charge an overview ScienceDirect Topics2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the A Review of the Grinding Media in Ball Mills for Mineral

Ball charges calculators thecementgrindingoffice

2018年7月24日 Ball top size (bond formula): calculation of the top size grinding media (balls or cylpebs):Modification of the Ball Charge: This calculator analyses the granulometry of the material inside the mill and proposes a modification of the ball charge in order to improve the mill efficiency:Metallurgist Mineral Processing Engineer2023年4月23日 One of the most used tumbling mills is the ball mill This paper reviews different types of grinding media that have been developed and improved over the years and their properties(PDF) Grinding Media in Ball MillsA Review ResearchGate2021年3月12日 process Together with ball charge composition, both tools – liners and media – can be optimally adjusted for the application They can then fulfil the Figure 2: ball mill tools and comminution process Figure 1: ball mill communition process chain Ball charge management grinding Ventilation and cooling Operation and controlBALL MILLS Ball mill optimisation Holzinger Consulting

.jpg)

What is the difference between a SAG mill and ball mill?

Ball mill A typical type of fine grinder is the ball mill A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls Ball mills normally operate with an approximate ball charge of 30%Pelletizing plant of the GolEGohar mining and industrial company consists of a burner, a dry ball mill (62 m × 13 m), and an air separator The ball mill consists of a 2 mlong drying and an 11 ExpandSimulation of ball charge motion in ball mills Semantic 2021年5月8日 Mill Speed = 75% Nc Ball charge level = 32% v/v Pulp density = 75% w/w Circulating load = 300% Discharge trunnion diameter = 13 m Motor Power draw = 47 MW Discharge trunnion diameter = 085 m Ball charge level = 35% v/v Motor Power draw = 47 MW Ausenco’s Ausgrind Expert Modelling Dia18 x EGL 31 ft : 5500 kW , 750 t/h Higher Rethinking Grinding Efficiency in Ball Mills RELO 2024年4月28日 The ball mills are mostly operated at 6575% of the critical speed to attain the best outcomes In this case, the media charge is estimated to be 3050% of the mill volume Using a greater number of What is a Ball Mill Explained: InDepth Guide

.jpg)

Ball Mill Grinding Machines: Working Principle, Types, Parts

Ball mill grinding machines are valuable tools in various industries, offering efficient and reliable grinding and mixing capabilities Understanding their working principle, different types, parts, applications, advantages, and recent developments helps to appreciate their significance and wideranging applications in industries such as cement Calculate and Select Ball Mill Ball Size for Optimum GrindingFor overflow ball mills, the charge should not exceed 45% of the mill volume For grate discharge mills, the charge should occupy about 50% of the mill volume Bond developed a relationship that can be used to determine the percent charge by volume as a function of the vertical height above the charge, He, and the radius of the mill, R, ie, AMIT 135: Lesson 7 Ball Mills Circuits2022年2月10日 Ball Charge Management Free download as Powerpoint Presentation (ppt), PDF File (pdf), Text File (txt) or view presentation slides online The document discusses ball charge management in ball mill systems It addresses the need to top up the ball charge as balls wear down over time to maintain grinding efficiency and production Ball Charge Management PDF Mill (Grinding) Nature

What Is a Ball Mill? Blog Posts OneMonroe

2020年3月10日 Materials are added to the ball mill, at which point the balls knock around inside the mill How a Ball Mill Works Ball mills work by using balls to grind materials Materials such as iron ore, pain and ceramics are added to the ball mill Next, the ball mill is activated so that it rotates — either on its vertical or horizontal axis As the 2024年9月11日 1 Ball Size Distribution in Ball Mills: The ball size distribution in a ball mill refers to the range of ball sizes used in the mill It is typically represented as a cumulative percentage of the total ball charge The optimal ball size distribution ensures maximum contact area between the balls, leading to efficient grindingBall size distribution in ball mills: Optimization and impact on 2024年8月8日 Ball Mill Success: A StepbyStep Guide to Choosing the Right Grinding Media {{lastDate}} Introduction In the intricate dance of ball milling, where raw materials are transformed into finely milled particles, the choice of grinding media emerges as a pivotal performance lever This seemingly minor selection can dramatically influence the Ball Mill Success: A StepbyStep Guide to Choosing the 2020年7月2日 When the mill charge contained monosized balls, the ball flow regime inside the mill transited to the cataracting and impact breakage was the main breakage mechanism Increasing the fraction of (PDF) Effects of Ball Size Distribution and Mill Speed and

Simulation of charge motion in ball mills Part 2: numerical

1994年2月1日 The friction between the ball charge and the mill shell can increase the power draft The center of the ball mass shifts in distance as much as 4% of the mill diameter during a complete rotation Finally, the distribution of collision energy and the spatial locations of high and lowenergy collisions are shown While many of the 2018年10月1日 To understand and describe the behavior of charge dynamics in mills, a series of dry and wet grinding tests were performed on a laboratoryscale ball mill The comparisons between experimental results and grinding media trajectory simulations were addressed Results show that the grinding media trajectory simulations exhibit a good Experimental study of charge dynamics in a laboratoryscale ball mill2023年6月28日 ball charging grinding media handling automatic safe sorting and handling of grinding media in the range 27mm to 150mm diameter 2 from delivery to mills ball storage winner innovation excellence award 2012 winner cy o'connor award for excellence in engineering technology 2012 transminauBALL CHARGING GRINDING MEDIA HANDLING2018年8月7日 Discrete element method (DEM) was used to study the effect of mill speed and lifter face angle on the characteristics of charge group Based on the bin algorithm, a position density limit is DEM Investigation of Mill Speed and Lifter Face Angle on Charge

.jpg)

PERI™ AutoCharge Mill Grinding Ball Charging System

Our PERI AutoCharge Mill Grinding Ball Charging System is designed to provide a controlled continuous supply of balls to maintain consistent ball loading in the grinding mill Continuously charging grinding balls will allow your mill to maintain a consistent power draft, charge volume, ore feed rate, or consumption average (kg/t) DOI: 101016/03017516(92)900769 Corpus ID: ; Optimization of the makeup ball charge in a grinding mill @article{Concha1992OptimizationOT, title={Optimization of the makeup ball charge in a grinding mill}, author={Fernando Concha and L Magne and Leonard G Austin}, journal={International Journal of Mineral Processing}, year={1992}, Optimization of the makeup ball charge in a grinding millBall Charge Ball mills for cement grinding usually operate with a filling degree between 25 and 35 % The filling degree is defined as the volume of the grinding media (balls) as a percentage of the total mill volume Since mill speed, liner shape and mill diameter are usually unchangeable parameters, the only adjustment in a mill can be made Process Training Ball Mill INFINITY FOR CEMENT EQUIPMENTThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or Ball Mill an overview ScienceDirect Topics

Ball charge optimization INFINITY FOR CEMENT EQUIPMENT

The raw mill will be operate with a much coarser ball charge than the cement mill mainly because of the bigger slot sizes of the partition wall The transition zone consists of 50 mm and 60 mm balls The basis is a 50 mm ball size for 5% residue on the 4 mm sieve In case bigger grains are bypassing the partition through the center grate even 2024年5月27日 Ball mills are widely used in the beneficiation process for various ores and minerals, including gold, copper, iron, and zinc The TITAN design enables you to run a full process load with a 40% ball Ball Mills in the Mineral Processing Industry2022年11月30日 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis Ball Mill: Operating principles, components, Autogenous and SemiAutogenous Mills In Mineral Processing Design and Operations (Second Edition), 2016 933 M ill Charge Usually, an SAG mill is charged to 30–35% of its interior volume The grinding balls occupy 5–15% of the volume [10]The charge volume can be estimated by measuring the distance between the top level of the charge and the Mill Charge an overview ScienceDirect Topics

.jpg)

A Review of the Grinding Media in Ball Mills for Mineral

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the 2018年7月24日 Ball top size (bond formula): calculation of the top size grinding media (balls or cylpebs):Modification of the Ball Charge: This calculator analyses the granulometry of the material inside the mill and proposes a modification of the ball charge in order to improve the mill efficiency:Ball charges calculators thecementgrindingofficeMetallurgist Mineral Processing Engineer2023年4月23日 One of the most used tumbling mills is the ball mill This paper reviews different types of grinding media that have been developed and improved over the years and their properties(PDF) Grinding Media in Ball MillsA Review ResearchGate

.jpg)

BALL MILLS Ball mill optimisation Holzinger Consulting

2021年3月12日 process Together with ball charge composition, both tools – liners and media – can be optimally adjusted for the application They can then fulfil the Figure 2: ball mill tools and comminution process Figure 1: ball mill communition process chain Ball charge management grinding Ventilation and cooling Operation and controlBall mill A typical type of fine grinder is the ball mill A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls Ball mills normally operate with an approximate ball charge of 30%What is the difference between a SAG mill and ball mill?