Iron Ore Concentrate Dryer

.jpg)

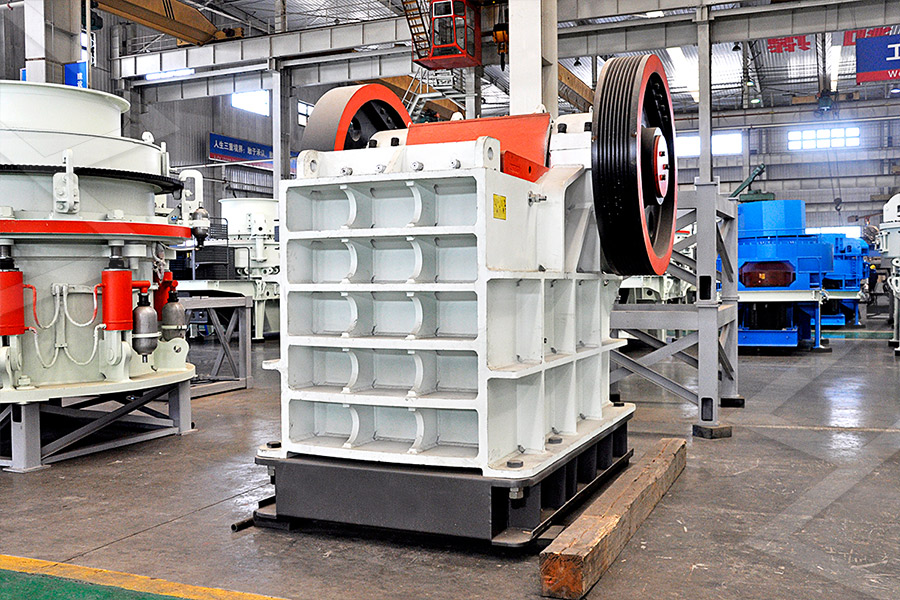

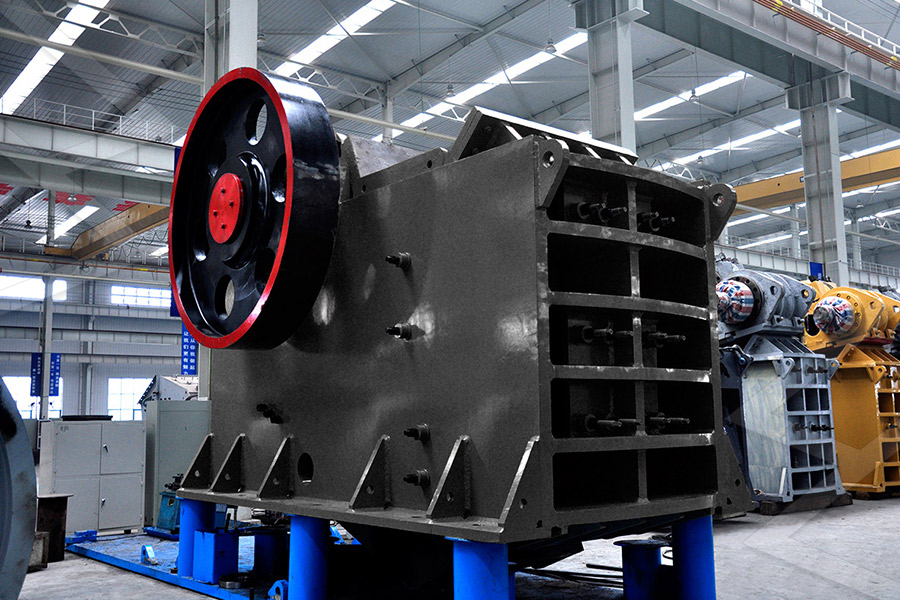

Large Capacity Iron Ore Dryer for Concentrate

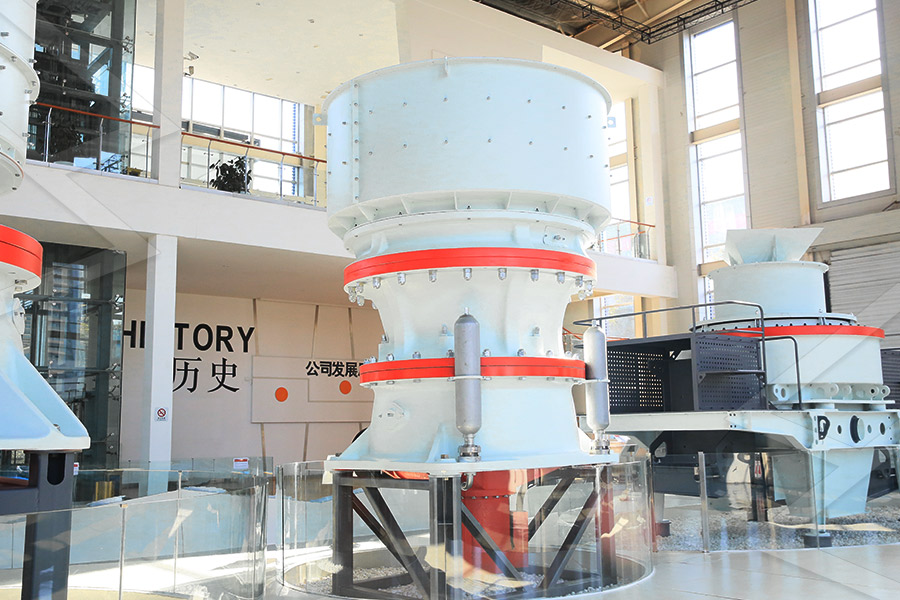

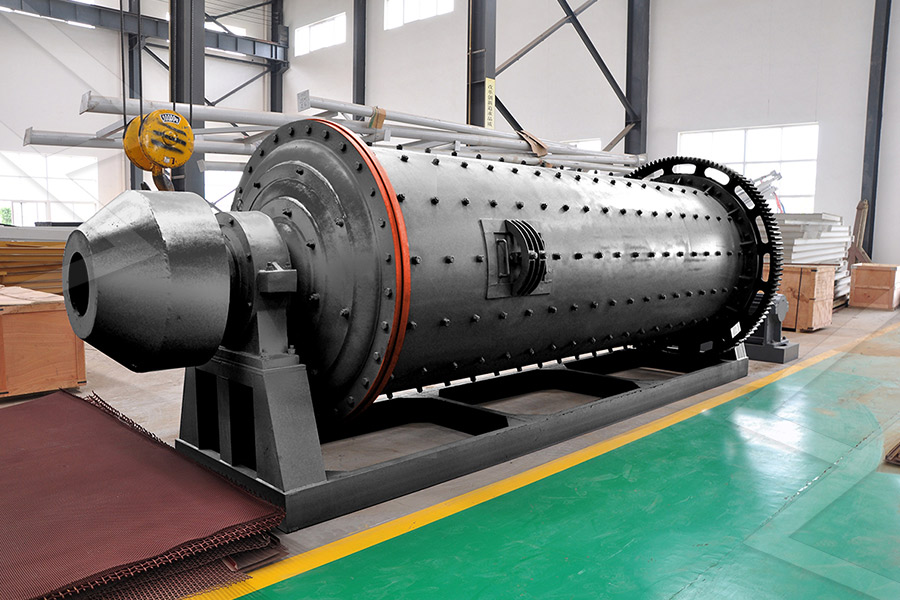

Iron ore dryer is specially designed on the basis of rotary drum dryer and combined with the characteristics of iron ore itself4 天之前 Mineral Slag (Ore) Dryer Application: Widely used for drying slag, mineral, ore, chrome concentrate, lithium ore slag, etcLarge Capacity Iron Ore Dryer for Drying This study offers theoretical support for simulating the drying of green ultrafine iron ore concentrate pellets and provides guidelines for selecting diverse drying conditions and BL Wen, XP Zhang, DL Liu, JX Li, XD Sun, JL Yang 2024年8月9日 Mineral Slag (Ore) Dryer Capacity: 3002000 t/d; Power 120500kw; Mineral slag dryer is widely used for drying slag, mineral, iron ore, chrome concentrate, Mineral Slag (Ore) DryerZhengzhou Jiutian Technology

.jpg)

Ilmenite Iron Ore Dryer Concentrate Dryer for Mining

2024年7月5日 Ilmenite Iron Ore Dryer Concentrate Dryer for Mining Factory, Find Details and Price about Mixed Concentrate Dryer Mineral Rotary Dryer from Ilmenite Iron Ore Browse wholesale iron ore concentrate dryer from Alibaba’s collection of drying equipment Find what you need online today at affordable prices you'll loveGet Great Deals Shopping for iron ore concentrate dryer2024年8月27日 Iron Concentrate Rotary Dryer Working Principle The iron ore concentrates is fed into the dryer uniformly and continuously through the belt conveyor The hightemperature hot air generated by the heating Iron Concentrate Rotary DryerChina Ore Concentrate Dryer wholesale Select 2024 high quality Ore Concentrate Dryer products in best price from certified Chinese Dryer Equipment manufacturers, Wood China Ore Concentrate Dryer, Ore Concentrate Dryer

High Efficient Minerals Iron Ore Rotary Dryer for Ore,

2024年6月22日 High Efficient Minerals Iron Ore Rotary Dryer for Ore, Mining, Quarry Aeras, Find Details and Price about Drum Dryer Rotary Dryer from High Efficient Metal powder dryer, also known as iron ore concentrate ball dryer or copper concentrate dryer, is a special piece of drying equipment developed for drying waste metal powderIt can effectively reduce the material moisture Metal Powder DryerIron Ore Concentrate Ball Additionally, the activation energy value of ultrafine iron ore concentrate for drying derived from the Arrhenius formula was 451560 J/(molK) Notably, increasing the drying temperature increased the strength of the dried particles due to their more compact and dense internal structure This study offers theoretical support for simulating BL Wen, XP Zhang, DL Liu, JX Li, XD Sun, JL Yang Iron ore dryer is also known as mineral dryer It is a rotary drum dryer widely used in iron ore pelletizing plants, therefore, it is also called iron ore pellet dryer During the production process, the raw material (iron ore Iron Ore Dryer – Rotary Dryer For Sale AGICO

.jpg)

Large Capacity Iron Ore Dryer for Drying

4 天之前 1 The ore slag constant speed quantitative feeder solves the feeding uniformity in the dryer, and overcomes the previous problems of intermittent feeding, material blocking, and large instantaneous material 2024年6月11日 Fig 1 Xray diffraction analysis of ultrafine iron ore concentrate Table 2 ultrafine iron ore concentrate physical properties (mass%) Raw material >0074 mm 0048– 0074mm 0038– 0048mm 0025–Study on the drying characteristics of green pellets of 2024年8月9日 Mineral Slag (Ore) Dryer Mineral slag dryer is widely used for drying slag, mineral, iron ore, chrome concentrate, lithium ore slag, copper concentrate, limestone, etc Capacity3002000 t/d; Heat source customizable; Power 120500kw; Email: Wechat/WhatsApp: +86 15617591790 GET QUOTEMineral Slag (Ore) DryerZhengzhou Jiutian Technology 2024年9月11日 Industrial Rotary Drum Dryer Drying Machine for Silica Sand, Sludge, Fly Ash, Iron Ore, Copper Concentrate, Coal Slime, Slag, Bentonite, Slurry, Find Details and Price about Sand Dryer Mineral Powder Dryer from Industrial Rotary Drum Dryer Drying Machine for Silica Sand, Sludge, Fly Ash, Iron Ore, Copper Concentrate, Coal Slime, Industrial Rotary Drum Dryer Drying Machine for Silica Sand,

Iron ore pellet drying assisted by microwave: A kinetic evaluation

ABSTRACT Drying is a critical process step to achieve excellent pellet quality in pelletizing process The complexity and energy consumption toward moisture removing, especially for highly hydrated iron ore, increased the need for breakthrough enhancements to this process The present study has evaluated kinetics parameters of the moisture release from iron 5 天之前 Iron ore oxidized pellet is a superior furnace burden for the blast furnace process, possessing high iron grades, good strength, and excellent metallurgical properties []Additionally, compared to the sintering process, the energy consumption of the pelletizing process is approximately 50% lower, with emissions of pollutants such as SO 2, NO x, A new insight into iron ore oxidized pellets prepared by steel Iron ore concentrates can be transported by all means of transport, provided that no contamination, mixture with any other materials or cargo spillage is ensured Drying during winter period Iron ore concentrate with Fe content more than 695% 7017 (minimum 695) 348 (maximum 35) Maximum 0045 mm / 9694 / not regulated; 7022 Iron ore concentrates Metalloinvest2023年11月6日 obtain iron ore concentrate with acceptable total iron (TFe) grades but ultrafine particle sizes [2,3] However, ultrafine iron ore concentrate fines can have an adverse effect on the permeability and productivity of sinter beds [4–9], pellets processing is still the preferred option [10,11]Green pellets drying is aStudy on the drying characteristics of green pellets of

Study on the drying characteristics of green pellets of ultrafine iron

Ultrafine iron ore concentrate pose challenges like poor pellets formation performance, lowbursting temperature, and a complex drying thermal regime To examine the drying characteristics of green pellets of ultrafine iron ore concentrate, we employed Weibull distribution function and Dincer model to fit and analyze the corresponding drying curve 2024年2月18日 A Copper Concentrate Dryer is the most suitable machine for this job It enables the operator to control drying temperature and time precisely Drying iron ore concentrates makes it easy to Applications of Rotary Dryers in Metal Concentrates: The In 2024年8月2日 This drying system is widely used in building material, chemical, mineral processing, refractory and other industries Application Iron Ore Concentrates Dryer System Iron Concentrate Rotary Dryer Iron Concentrate Rotary DryerDongding Drying 2024年7月24日 Utilizing ultrafine iron ore concentrate for pellet production can expand domestic iron ore resources in China and promote the utilization of lowgrade ores However, a challenge arises with the low decrepitation temperature and reducibility in the preparation process of ultrafine iron ore concentrate pellets To address the challenge, a A novel approach to enhance decrepitation temperature and

Features of the Iron Ore Pellets Structure Depending on the Concentrate

2023年7月4日 Abstract Aspects of the pellets structure are analyzed: the phase composition; features of interphase element migration; size of crystals of individual phases and their mutual arrangement; porosity; zoning; metallurgical properties The structural features of pellets that determine their metallurgical properties include the nature of 2022年10月19日 Drying operations in iron ore processing plants have a particularly high energy demand due to the massive solid flow rates employed in this industryEnergy analysis of the convective drying of iron ore fines2018年1月17日 To examine the drying characteristics of green pellets of ultrafine iron ore concentrate, we employed Weibull distribution function and Dincer model to fit and analyze the corresponding drying curveIron ore pellet drying assisted by microwave: A kinetic evaluationDrying may be an important aspect of mineral processing; throughout the journey from ore to end product, the flexibility to manage moisture content helps to reduce shipping prices, streamline downstream process, and manufacture a refined product While mineral dryers could appear a similar as different industrial dryers, they’re usually designed to withstand Drying Technologies for Mineral Raw Materials Kerone

.jpg)

Study on the drying characteristics of green pellets of ultrafine iron

2023年12月1日 Ultrafine iron ore concentrate pose challenges such as poor pellet formation performance, lowbursting temperature, and a complex drying thermal regime To examine the drying characteristics of green pellets made from ultrafine iron ore concentrate, the Weibull distribution function and Dincer model were employed to fit and analyze the 2018年1月17日 ABSTRACT Drying is a critical process step to achieve excellent pellet quality in pelletizing process The complexity and energy consumption toward moisture removing, especially for highly hydrated iron ore, increased the need for breakthrough enhancements to this processIron ore pellet drying assisted by microwave: A kinetic evaluation2022年12月11日 This study present the systemlevel dynamic performance and technoeconomic optimisation of solarthermal beneficiation of iron ore Fig 1 illustrates the schematic diagram of the dynamic model for the proposed solarthermal beneficiation plant The whole process is composed of the following units: the airbased PTC, the rockbed Solarthermal beneficiation of iron ore: Systemlevel dynamic 2023年5月22日 Concentrate dryer is specialized for drying metal ore machine, it has high drying efficiency, fast speed, long working time characteristics For common industrial ores, such as copper concentrate, Concentrate Drying Process MECRU Heavy

Cold plasma treatment: An innovative approach to reduce

2024年5月23日 Abstract Wet beneficiation is a primary process employed by mining companies for iron ore concentration The moisture content in the ore is a result of this beneficiation process, in addition to inherent moisture within the mineral composition The moisture content of iron ore is a crucial parameter that requires effective control to 2018年10月1日 As the ultrafine iron ore concentrate was used to prepare green pellets, the main problem was the serious cracking during the drying process The fine particles contacted so closely that the Improvement on the thermal cracking performance of pellets prepared 2022年8月29日 The slag dryer together with the ore powder dryer, quartzite dryer, copper concentrate dryer is widely used by the industries of construction materials, metallurgy, ore beneficiation, chemical engineering and cement making to dry materials such as slag, carbide slag, lime stone, clay, river sand, silica sand and grain slag, etcSlag Dryer, Ore Powder Dryer, Quartzite Dryer, Copper Concentrate Dryer 2024年5月27日 The raw materials were dried at 120 °C for 24 h in a forcedair drying cabinet, followed by ball milling of the iron ore and anthracite The size distribution characteristics of the raw materials after crushing are presented in Table 3It can be clearly seen that both iron ore concentrate and anthracite powder exhibit a wide range of particle Mechanism of thermal compressive strength evolution of

.jpg)

Kinetics of Reduction in Stages of Pellets Prepared from the

2022年2月27日 To explore the reduction swelling process of pellets prepared from the Bayan Obo iron ore concentrate, based on the iron oxide reduction theory of pellets, the reduction of pellets prepared from the Bayan Obo iron ore concentrate was analyzed by thermogravimetric experiments and kinetic calculations in three stages The reason for 2015年5月4日 Iron ore concentrate pellets are traditionally hardened at high temperatures in horizontal grates and gratekiln furnaces However, heat induration requires tremendous quantities of energy to produce highquality pellets, and is consequently expensive Cold bonding is a lowtemperature alternative to heat induration Pellets can be cold bonded Cold Bonding of Iron Ore Concentrate Pellets Semantic Ultrafine iron ore concentrate pose challenges like poor pellets formation performance, lowbursting temperature, and a complex drying thermal regimeChemical composition of ultrafine iron ore concentrate Additionally, the activation energy value of ultrafine iron ore concentrate for drying derived from the Arrhenius formula was 451560 J/(molK) Notably, increasing the drying temperature increased the strength of the dried particles due to their more compact and dense internal structure This study offers theoretical support for simulating BL Wen, XP Zhang, DL Liu, JX Li, XD Sun, JL Yang

Iron Ore Dryer – Rotary Dryer For Sale AGICO

Iron ore dryer is also known as mineral dryer It is a rotary drum dryer widely used in iron ore pelletizing plants, therefore, it is also called iron ore pellet dryer During the production process, the raw material (iron ore 4 天之前 1 The ore slag constant speed quantitative feeder solves the feeding uniformity in the dryer, and overcomes the previous problems of intermittent feeding, material blocking, and large instantaneous material Large Capacity Iron Ore Dryer for Drying 2024年6月11日 Fig 1 Xray diffraction analysis of ultrafine iron ore concentrate Table 2 ultrafine iron ore concentrate physical properties (mass%) Raw material >0074 mm 0048– 0074mm 0038– 0048mm 0025–Study on the drying characteristics of green pellets of 2024年8月9日 Mineral Slag (Ore) Dryer Mineral slag dryer is widely used for drying slag, mineral, iron ore, chrome concentrate, lithium ore slag, copper concentrate, limestone, etc Capacity3002000 t/d; Heat source customizable; Power 120500kw; Email: Wechat/WhatsApp: +86 15617591790 GET QUOTEMineral Slag (Ore) DryerZhengzhou Jiutian Technology

Industrial Rotary Drum Dryer Drying Machine for Silica Sand,

2024年9月11日 Industrial Rotary Drum Dryer Drying Machine for Silica Sand, Sludge, Fly Ash, Iron Ore, Copper Concentrate, Coal Slime, Slag, Bentonite, Slurry, Find Details and Price about Sand Dryer Mineral Powder Dryer from Industrial Rotary Drum Dryer Drying Machine for Silica Sand, Sludge, Fly Ash, Iron Ore, Copper Concentrate, Coal Slime, ABSTRACT Drying is a critical process step to achieve excellent pellet quality in pelletizing process The complexity and energy consumption toward moisture removing, especially for highly hydrated iron ore, increased the need for breakthrough enhancements to this process The present study has evaluated kinetics parameters of the moisture release from iron Iron ore pellet drying assisted by microwave: A kinetic evaluation5 天之前 Iron ore oxidized pellet is a superior furnace burden for the blast furnace process, possessing high iron grades, good strength, and excellent metallurgical properties []Additionally, compared to the sintering process, the energy consumption of the pelletizing process is approximately 50% lower, with emissions of pollutants such as SO 2, NO x, A new insight into iron ore oxidized pellets prepared by steel Iron ore concentrates can be transported by all means of transport, provided that no contamination, mixture with any other materials or cargo spillage is ensured Drying during winter period Iron ore concentrate with Fe content more than 695% 7017 (minimum 695) 348 (maximum 35) Maximum 0045 mm / 9694 / not regulated; 7022 Iron ore concentrates Metalloinvest

Study on the drying characteristics of green pellets of

2023年11月6日 obtain iron ore concentrate with acceptable total iron (TFe) grades but ultrafine particle sizes [2,3] However, ultrafine iron ore concentrate fines can have an adverse effect on the permeability and productivity of sinter beds [4–9], pellets processing is still the preferred option [10,11]Green pellets drying is a