Gold Ore Crusher Ball Mill

.jpg)

Gold Ore Crushing Grinding Equipment Jaw Crusher and Ball Mill

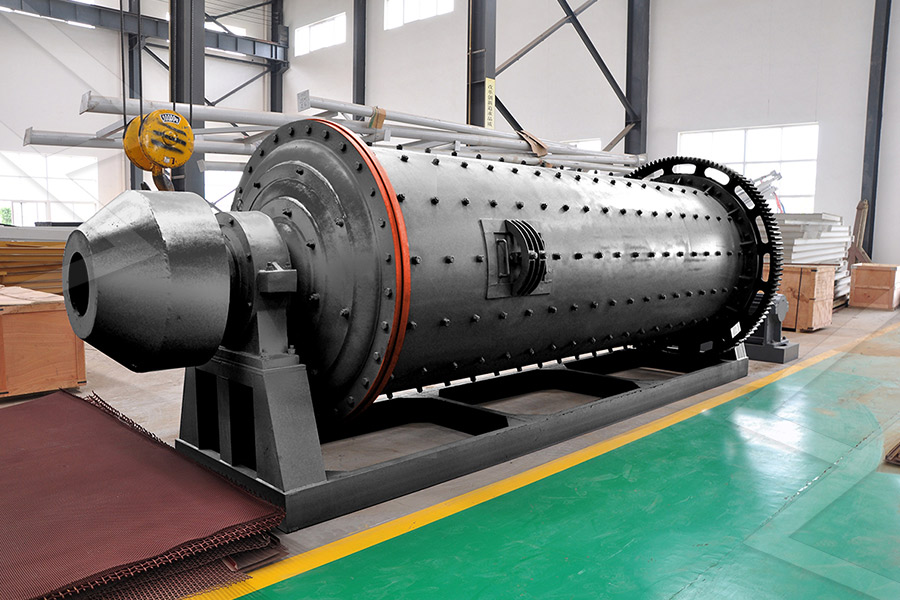

2024年8月30日 Gold Ore Crushing Grinding Equipment Jaw Crusher and Ball Mill China Ball Mill and Grinding Mill US$8,00000/ Set 1 Set (MOQ) Product Details 2016年1月1日 For modern large gold plants, the most typical flowsheets are crushing circuits (for heap leaching), autogenous/semiautogenous (AG/SAG) ballmill circuits, or Comminution Circuits for Gold Ore Processing ScienceDirect2 天之前 The main component of ball mill is a cylinder with smaller diameter and larger length, which rotates slowly through the transmission device The material is fed into the China Top Grinder Machine Industry Gold Ore Ball MillOur ball mills are industrial grade and designed for continuous operation, equipped with oversize roller bearings and a complete drive system All wear parts are highly abrasion resistant and replaceable The capacity, or Ball Mills Mt Baker Mining and Metals

.jpg)

Ball Mill Gold Mining Equipment Rock Crusher Wet Type Grinding Mill

2024年9月11日 Associated gold mine process: It includes depleted sulfide gold ore, polysulfide gold ore, goldbearing polymetallic ore, telluridebearing goldgold ore, gold 2024年9月11日 Gold mining ball mills are integral equipment used in the gold mining process, designed to grind and crush ore materials These mills are crucial for the The significance of gold mining ball mills in the modern QMJ series Ball Mill for gold mining features and technical advantages high efficiency Our Ball Mill for gold mining adopts rolling bearing support instead of sliding bearing support Ball Mill for gold mining sandmancrusherOre ball mill is mainly used for crushing and grinding of different kind of ores, and can be widely used in cement, ore dressing, building materials, refractory materials, chemicals, Gold Ore Ball Mill Factories Manufacturer Tongli Machinery

.jpg)

Ball Mill Mining Grinding Mill JXSC Machinery

2 天之前 1 The ball mill can efficiently and finely grind various materials with different hardness and abrasion properties, including metallic ores, nonmetallic ores, cement clinker, etc 2 It has a highly automated control 2023年8月14日 Gold Ore Processing Mill Crushes Quartz and Mining Rock Ore to Release Gold a high output / dual adjustable discharge / heavy duty version flail impact rock crusher gold mill that is very portable and GS4000HV Gold Stryker Gold Ore Impact Flail 2019年8月14日 • Central discharge ball mill: the inlet of medium unloading ball mill is at both ends, and the outlet is in the middle of the ball mill 4 According to the ore discharge of ball mill: • Overflow ball mill: Discharge the ore through hollow shaft • Grid ball mill: Discharge the ore through the plaid plateThe Ultimate Guide to Ball Mills Miningpedia2023年8月14日 Gold Stryker® GS7000 LD is a very large flail impact rock crusher gold mill that is very portable and perfect for the small gold mining operation The Gold Stryker® GS7000LD uses a large 25 HP Honda Industrial engine for many years of trouble free use It can process and crush up to 7 tons in a day, all the way down to #300 mesh through Gold Ore Impact Flail Processing Rock Quartz Crush Mill gold mill

Rock Gold Mining Equipment And Technologies Eastman Rock Crusher

2024年6月12日 Firstly, the jaw crusher is for roughly crushing the gold ore, and then the cone crusher is for intermediate crushing Grinding stage; The equipment for the grinding stage is a ball mill to grind the gold ore from the cone crusher The feed particle size is 2025mm, and the discharge particle size is 0074089mm Gold ore gravity separation stage2022年5月19日 In general, only the dissociation of the sulfide ore monomer is required for gold encapsulated in sulfide minerals However, for the gold that is continuous with the gangue, the grinding fineness needs to reach the dissociation of the gold monomer Gold grinding and classification machines: Wet grid ball mill, wet overflow ball mill, hydrocycloneHow to Process Gold Ore? 4 Gold Processing Steps Mining 2018年6月14日 The ore is sent into a singlecylinder hydraulic cone crusher for the secondary crushing Thereafter, the gold ore is transferred to a multicylinder hydraulic cone crusher, where the ore is crushed further into finer material From there, the crushed gold ore is sent to a ball mill, evenly as it passes through a vibrating screen for grindingUsing Ball Mills to Extract Raw Gold from Ores2022年11月2日 Our Gold Stryker® GS 5000HV is a extreme duty high quality made here in the USA flail impact gold mill that can process and crush up to 5 tons of rock in a day, all the way down to #300 mesh through the mill to release the gold Perfect for the small gold mining operation The Gold Stryker® GS 5000HV measures 4 1/2 feet tall and has a GS5000 Gold Stryker Gold Ore Impact Flail Processing Rock gold mill

.jpg)

Mining/Ore Milling Mt Baker Mining and Metals

We use a variety of machinery combinations to liberate the gold and concentrate it for recovery The allinclusive TurnKey Ore Processor will take a loaderbucket of ore and produce concentrated gold and sulfides with no handson activity by the operator For a less costly production system, using handfed machinery, we offer a jaw crusher, hammer Metallurgist Mineral Processing EngineerUnlocking the Secrets of Gold Ore Mill: A Comprehensive Guide; Gold Ore Crusher Stutenroth Impact Mill – GameChanging Gold Mining Machinery Other options such as jaw crushers or ball mills may have their own unique advantages depending on specific needs and operational requirements If you’re looking for a reliable and efficient Stutenroth Impact Mill – GameChanging Gold Mining 2020年1月16日 The SAG mill circuit also includes a singledeck screen and a cone crusher while the ball mill circuit utilizes hydrocyclones The mine treats a sulphide coppergold ore to produce gold in (PDF) Optimization and performance of grinding

.jpg)

MiniMobile Gold Processor Mt Baker Mining

MiniMobile Gold Processor One of our unique designs combines a sluice connected directly to the hammer mill outlet The hammer mill is a standard 16″ x 12″ powered by a 22 hp gasoline engine and will accept a feed size 2024年9月11日 Additionally, the ball mill’s versatility allows parameters such as speed, feed rate and material composition to be adjusted, making it adaptable to different types of lithium ore This flexibility is essential to optimize the grinding process for each specific ore type, thereby increasing cost efficiency and resource sustainabilityBall Mill Is The Key To Grinding Lithium Ore JXSC MachineryMobile Stone Iron Gold Ore Rock Mining 100150 Tph Jaw Crusher Manufacturers Price Portable Granite Crushing Machine Plant for Sale US$8,9600029,64600 / Set 1 Set (MOQ) China Good Quality Energy Saving 35tph Wet Gold Ball Mill Machine for Grinding Quartz Limestone Gold Ore Factory Price US$6,0000036,50000 / Set 1 Set (MOQ)Jaw Crusher Manufacturer, Hammer Cruser, Cone Crusher 3 天之前 EFFICIENCY: SPEEDMINER ® Mobile Fully Integrated Hard Rock plant is designed with advanced technology to ensure 100% recovery of gold and other metals production, with no loss PRODUCT RANGE: SPEEDMINER ® Mobile Hard Rock plants are produced in 13 standard models with capacity range of 2120 TPH SELFSUFFICIENT MOBILE HARD ROCK GOLD MINING EQUIPMENT

The significance of gold mining ball mills in the modern

2024年9月11日 Gold mining ball mills are integral equipment used in the gold mining process, designed to grind and crush ore materials These mills are crucial for the extraction of gold from ore and play a significant role in the production of gold worldwide 1 Understanding Gold Mining Ball Mills: Gold mining ball mills are grinders that are used to 2024年8月22日 The Gold Flotation Process means that gold ore is generally crushed by gold mining equipment (crusher equipment, Jaw crusher), crushed by gold processing equipment (ball mill), and treated by gold panning equipment such as flotation machine, etc Through gravity separation, flotation machine, extraction of metals from ores, and then Gold Flotation JXSC Machine2023年7月31日 Gold Ore Ball Mill Models: Gold ore ball mill models have complete specifications and are suitable for different sizes of gold processing plants The cylinder diameter of gold ore ball mills ranges from 06m to 45m, with production capacities ranging from 065t/h to 615t/h Small gold ball mills, with cylinder diameters below 21m, have Gold ore ball mill common model and price, how to match 5 天之前 It takes large pieces of rock, ore, concrete, or other materials, and crush them down to smaller sizes for further processing in a ball mill or hammer crusher It is widely used in mining, metallurgy, building materials, road, railway, road, slag for crushing various materials with compression strength less than 350 MpaPE600X900 Mobile Stone Rock Gold Ore Jaw Crusher Machine

.jpg)

Exploring Ball Mill Diagram: A Comprehensive

2024年4月28日 The speed of ball mill rotation is a critical parameter which determines the grinding efficiency and the end product quality The optimum speed will differ depending on the mill’s diameter, the size and density of The company's main products are crushers, Grinding mill equipment, mineral beneficiation equipment, rotary dryer and crusher grinding mill Spare Parts In addition to the Chinese domestic market, Ascend machinery expands its business in Jaw Crusher,Ball Mill,Mining Crusher,Mining Equipment 2024年8月22日 A batch ball mill is a machine to grinds the crushed materials, which is widely used in the manufacturing industries, such as cement, silicate, new building material, refractory material, fertilizer, Batch Small Ball Mill JXSC Machine2024年1月10日 Ore discharge method Ball mills can be divided into overflowtype and gridtype, while rod mills are classified into overflowtype and opentype rod mills Among ball mills, the commonly used ones are gridtype ball mills and overflowtype ball mills (named from different structures of the ore discharge parts), while rod mills do not use Ball Mill VS Rod Mill: Difference Selection JXSC Machine

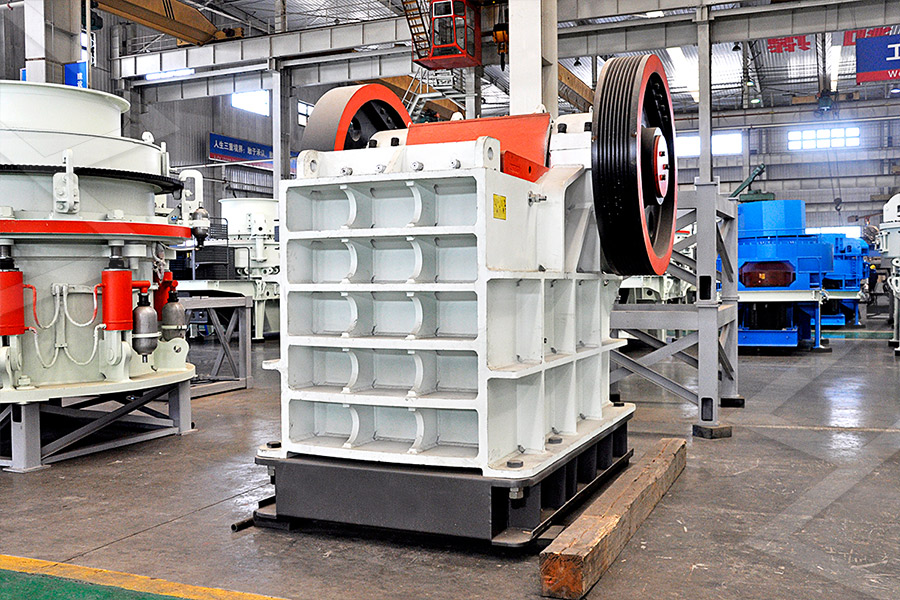

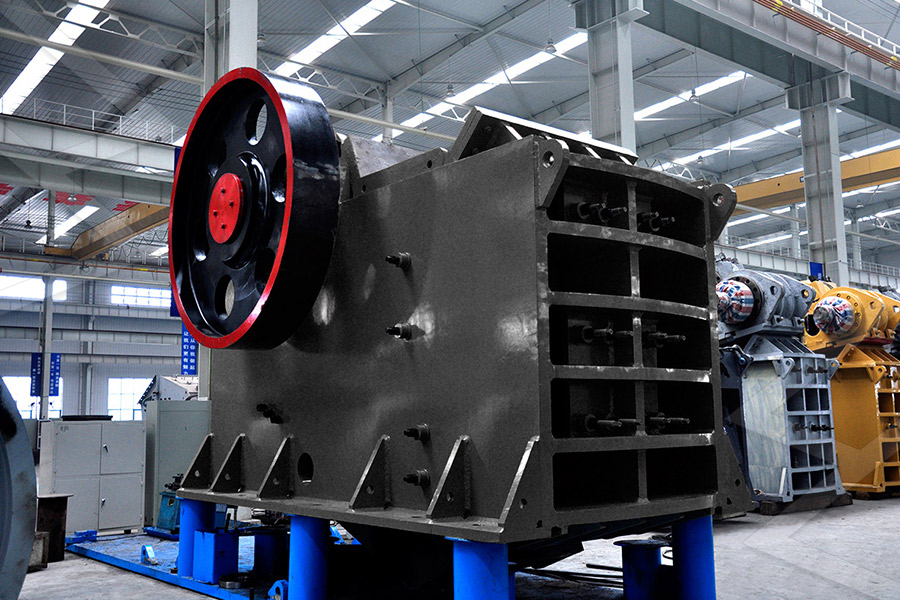

Crusher Machine for Gold Mining Plant Gold Crusher Zenith Crusher

2019年10月14日 Gold mining machine has an important role in gold mining industry We are a professional gold mining machine manufacturer, We produce gold ore crusher and gold ore grinding machines and lot of gold ore beneficiation line for your choose, In gold mining, high technology gold mining equipment, such as gold detectors, elegant modern 2023年10月4日 Grinding Balls: Grinding balls are spherical components used in grinding mills to crush and grind raw materials, turning them into fine powders These balls are essential in the mining industry to extract valuable minerals from ore Steel Grinding Balls: Steel grinding balls are a subset of grinding balls, specifically made from highquality steelMining Balls: The Backbone of Material Processing3Gold ore flotation process plant Gold flotation process is divided into several parts, such as crushing, grinding and flotation etcIt will be used jaw crusher, ball mill, spiral classifier, flotation machine, the mixing tank, thickener and other equipment Application scope:Gold ore processing plant XKJ Group,Crusher,Ball mill2024年8月30日 small ball mill, 900x1800 ball mill, bal mill for gold mining Application of Different Types Of Ball Mills In Iron Ore Beneficiation DOWNLOAD THE COPY International Exhibition See more NEW PE600x900 Jaw Crusher for 100150tph Stone Crushing Plant 3 plays BAICHY PE750x1060 Jaw Crusher Aggregate Equipment 3 Small Ball Mill 900x1800 Ball Mill for Gold Mining Baichy

Gold Ore Processing Solution Eastman Rock Crusher

Ball mill is a commonly used and efficient grinding equipment It is suitable for grinding various ores such as iron ore, gold ore, gold ore and leadzinc ore in metal beneficiation, and is used to grind the ore to below 0075mm for subsequent beneficiation processes2023年6月2日 crusher, grinding mill Published Jun 2, 2023 + Follow A ball mill is a grinding machine used to grind, blend, and sometimes for mixing of materials for use in mineral dressing processes, paints Ball Mill For Gold Ore LinkedInCorporate Headquarters Star Trace Solutions Pvt Ltd No: 48, TVK Street, Redhills, Chennai 600 052, Tamil Nadu, India PhNo +91 44 , Gold Processing Equipment Star Trace Solutions Pvt LtdMaksimalkan produktivitas dan presisi dengan mesin ball mill Jelajahi beragam penerapannya di berbagai industri Keunggulan Yang Membuat Grinding Ball Mill Menonjol Ball mill advantages terletak pada daya Mesin Ball Mill Penggilingan dan Pembuatan

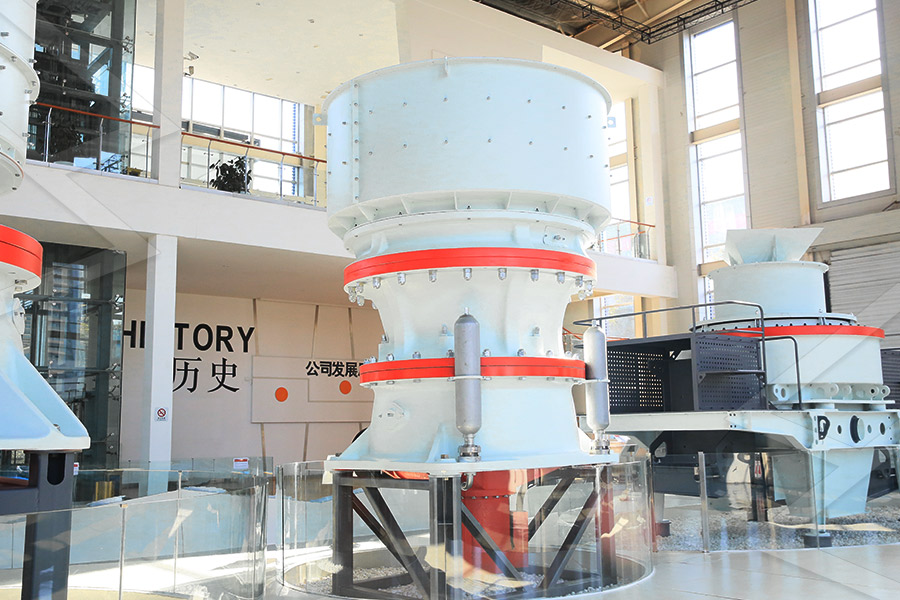

Beneficiation of Gold and Silver Ores SpringerLink

2019年12月15日 429 VertiMills Vertical mills were first designed in the 1950s for applications in fine and ultrafine grinding in Japan Lately, the vertical mill is making progress toward primary grind application and shown promise in energy reduction relative to ball mills, typical to what is normally seen in regrinding applications (Mazzinghy et al 2014) 2024年9月11日 The advantage of the grid type ball mill is that the ore discharge speed is fast, it can reduce the overcrushing of ore, and at the same time it can increase the output per unit volume 1 Large row of ore mouth design, stronger processing capacity for lithium ore, up to 160t/h; 2 Equipped with an automatic control system PLC, reducing labor Ball Mill Is Indispensable For Lithium Ore Processing5 天之前 Basic knowledge of ball mill machine Production capacity: 065615 tons/hour Application: Used in various industries, such as cement, new building materials, refractory materials, silicate products, fertilizers, black and nonferrous metal beneficiation, and glass ceramics, for dry or wet grinding of various ores and other grindable materials Ball Mill For Sale Factory Price Timely Service2023年3月16日 The ball mill is widely used in the mineral processing plant, besides, we can also provide other rock crusher machines and mill grinding machines for a complete mineral processing plant like gold, copper, iron, etc Eastman Technology has a technical team to provide presale and aftersale services Welcome to inquiring, and get What Is Ball Mill? Eastman Rock Crusher

.jpg)

AIMIX Ball Mill For Sale For Gold Mining Processing

The ball mill is the key equipment for crushing materials after they have been crushed It is suitable for grinding ores and other materials and is widely used in nonferrous metal mining, nonmetallic mining building materials, the chemical industry, electric power, coal, transportation, cement, silicate products, new building materials, refractory materials, and 2024年4月28日 Critical Speed: Critical speed is the hypothetical speed at which the centrifugal force is equal to the gravitational force, and the grinding media starts sticking to the inner shell of the equipment instead of falling freelyGrinding at or close to critical speed of the mill yields a poorer grinding efficiency The ball mills are mostly operated at 65 What is a Ball Mill Explained: InDepth Guide JXSC3 天之前 DOVE Ball Mills are supplied in a wide variety of capacities and specifications DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h1000 g/h) For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity range of (03 TPH – 80 TPH)Ball Mill Ball Mills Wet Dry Grinding DOVE2024年4月9日 What are the models of gold ore ball mills? Gold ore ball mills are classified based on the mill diameter and loaded capacity Several popular models are available, with different specifications to suit various mining and mineral processing applications Here are some common models of gold ore ball mills: 1 Wet Overflow Ball Mill:What are the models of gold ore ball mills? NEWS

Ball Mill Mining Grinding Mill JXSC Machinery

2 天之前 1 The ball mill can efficiently and finely grind various materials with different hardness and abrasion properties, including metallic ores, nonmetallic ores, cement clinker, etc 2 It has a highly automated control 2023年8月14日 Gold Ore Processing Mill Crushes Quartz and Mining Rock Ore to Release Gold a high output / dual adjustable discharge / heavy duty version flail impact rock crusher gold mill that is very portable and GS4000HV Gold Stryker Gold Ore Impact Flail 2019年8月14日 • Central discharge ball mill: the inlet of medium unloading ball mill is at both ends, and the outlet is in the middle of the ball mill 4 According to the ore discharge of ball mill: • Overflow ball mill: Discharge the ore through hollow shaft • Grid ball mill: Discharge the ore through the plaid plateThe Ultimate Guide to Ball Mills Miningpedia2023年8月14日 Gold Stryker® GS7000 LD is a very large flail impact rock crusher gold mill that is very portable and perfect for the small gold mining operation The Gold Stryker® GS7000LD uses a large 25 HP Honda Industrial engine for many years of trouble free use It can process and crush up to 7 tons in a day, all the way down to #300 mesh through Gold Ore Impact Flail Processing Rock Quartz Crush Mill gold mill

Rock Gold Mining Equipment And Technologies Eastman Rock Crusher

2024年6月12日 Firstly, the jaw crusher is for roughly crushing the gold ore, and then the cone crusher is for intermediate crushing Grinding stage; The equipment for the grinding stage is a ball mill to grind the gold ore from the cone crusher The feed particle size is 2025mm, and the discharge particle size is 0074089mm Gold ore gravity separation stage2022年5月19日 In general, only the dissociation of the sulfide ore monomer is required for gold encapsulated in sulfide minerals However, for the gold that is continuous with the gangue, the grinding fineness needs to reach the dissociation of the gold monomer Gold grinding and classification machines: Wet grid ball mill, wet overflow ball mill, hydrocycloneHow to Process Gold Ore? 4 Gold Processing Steps Mining 2018年6月14日 The ore is sent into a singlecylinder hydraulic cone crusher for the secondary crushing Thereafter, the gold ore is transferred to a multicylinder hydraulic cone crusher, where the ore is crushed further into finer material From there, the crushed gold ore is sent to a ball mill, evenly as it passes through a vibrating screen for grindingUsing Ball Mills to Extract Raw Gold from Ores2022年11月2日 Our Gold Stryker® GS 5000HV is a extreme duty high quality made here in the USA flail impact gold mill that can process and crush up to 5 tons of rock in a day, all the way down to #300 mesh through the mill to release the gold Perfect for the small gold mining operation The Gold Stryker® GS 5000HV measures 4 1/2 feet tall and has a GS5000 Gold Stryker Gold Ore Impact Flail Processing Rock gold mill

Mining/Ore Milling Mt Baker Mining and Metals

We use a variety of machinery combinations to liberate the gold and concentrate it for recovery The allinclusive TurnKey Ore Processor will take a loaderbucket of ore and produce concentrated gold and sulfides with no handson activity by the operator For a less costly production system, using handfed machinery, we offer a jaw crusher, hammer Metallurgist Mineral Processing Engineer